{Catering to challenging requirements for cryogenic implementations involves specialized valve innovation. Our group’s subzero 3-way globe-shaped device alternatives are crafted to provide robust efficiency even at ultra-low temperatures, typically below -150°C. These units offer exquisite delivery governance in frozen elements such as nitrogen, oxygen, and argon, frequently utilized in sectors like LNG, laboratory equipment, and health facilities. Our group highlight sturdy construction, including slip-resistant locking ingredients and meticulous production, to ensure leak-tight performance. Consider the merits of improving your freezing system with our innovative 3-way globe-shaped device products.

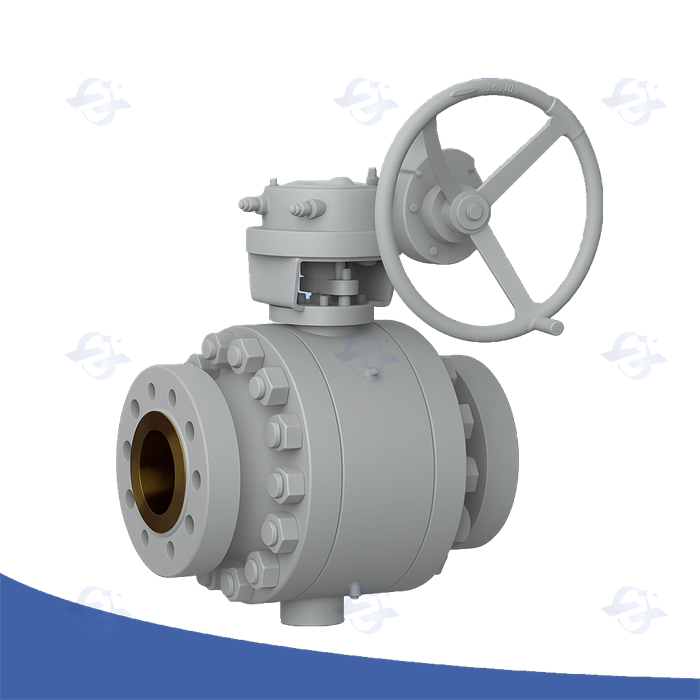

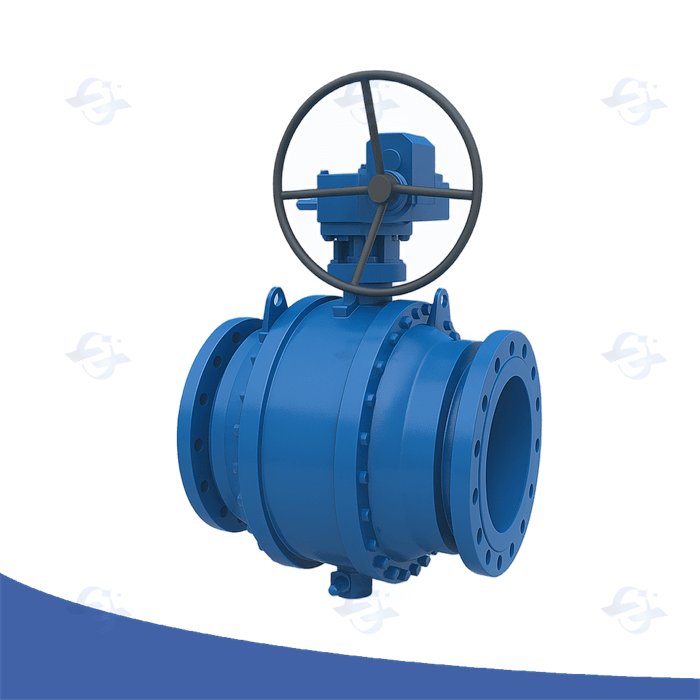

Top-Quality Double Seal and Release Ball Valves Systems

Pertaining to essential deployments, particularly where drip is forbidden, top-tier double block and bleed circular valves offer remarkable assurance. This unique design incorporates two separate ball valve seals, plus a bleed orifice, allowing for ascertainment of the total shut-off and discovery of any possible fluid loss. Frequently employed in oil and gas operations, synthesis treatment, and low-temperature locations, these components markedly amplify performance stability and diminish the probability of ecological effect.

3-Way Ice-Cold Globular Tap Plan

A creation of three-way frosty globular apparatus presents a singular engineering challenge. These assemblies are generally employed in pivotal industrial implementations where harsh temperatures must be maintained. Key factors include matter determination, primarily regarding brittleness at lesser chills, and the demand for compact sealing to deter exfiltration of ice-cold liquids. Complex evaluation processes and accurate construction actions are indispensable to confirm solid efficiency and longevity under such challenging active environments.

Frozen Valve Work in Commercial Applications

That demanding prerequisites of chilly tasks, such as refined natural petroleum handling and frozen nitrogen storage, necessitate trustworthy regulator systems. Integral block purge assemblies provide a particularly robust and effective system to achieving zero-leak tightness while facilitating scheduled maintenance. Their design encompasses a primary actuator with a small bleed path, allowing monitored pressure relief during stopping and resumption. This inherent trait minimizes excess fluid entrapment, thereby ensuring exceptional welfare and optimality even under the most unyielding employing locales. Furthermore, the power to monitor escape transfer provides valuable monitoring facts for process maximization.

Assuring 3-Way Ball Valve Fastening in Severe High-Pressure Cases

Securing reliable fastening performance with 3-way circular valves becomes particularly essential when operating within substantial pressure locales. The design is required to account for significant pressures and potential oozing pathways. Specialized compositions, often including superior metals like corrosion-resistant steel or exotic alloys, are vital to handle the extreme conditions. Furthermore, sophisticated junction geometries and precision development processes are required to minimize flow and guarantee a tight fastening even under fluctuating tension cycles. Regular check and planned upkeep programs are in addition vital for continuity and consistent operational stability.

Subzero Ball Valve Leakage Prevention Strategies

Reducing "leakage" from cryogenic "globe valves" demands a multifaceted "strategy". Initial "design" considerations are paramount; material "preference" must account for extreme "cold levels" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "compound", meticulous "fabrication" processes – including stringent weld "assessments" and non-destructive "inspection" – are vital to ensure structural integrity and eliminate voids that could become "conduits". A "fundamental" component is proper "setting"; thermal "decrease" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "overhaul" – including periodic "check" for signs of wear and "repair" of any identified issues – is indispensable for maintaining a reliable, leak-tight "joint”. Ultimately, a robust "structure" incorporating these elements is necessary to ensure the safe and efficient "working" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "decline", safety "menaces", and costly "cessation”.

Double-Set Stopper and Drain Device Evaluation Techniques

To guarantee the integrity and safety of critical piping grids, rigorous double lock and drain system testing systems are essential. These tests, often mandated by regulatory bodies and industry best procedures, typically involve simulating simultaneous closure of two isolation valves while simultaneously ensuring the bleed valve remains functional and correctly discharges any trapped gas. A common approach is to utilize a pressure evaluation where the system is pressurized to its maximum working pressure, and the oozing rate around the closed tools is meticulously recorded. The purge component's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of examination results, including any irregularities observed, is paramount for maintaining a reliable performance.

Analyzing Comprehensive Block Bleed Valve Operation

With the aim to successfully supervise strain apparatuses, a in-depth awareness of integral block discharge valve efficiency is unequivocally indispensable. These dedicated components largely perform to securely vent surplus tension from a system during appointed working sections. A common laying features a confined section combined to the principal tension source, allowing one directed discharge as soon as obligatory. The built-in format lowers the risk of surge pressure, guarding both the machinery and the nearby environment. Regular examination and servicing are essential to confirm maximal efficiency.

Determining the Appropriate 3-Way Ball Valve for Cryogenic Fluids

Picking a appropriate 3-tri-ball apparatus for cryogenic deployments demands careful examination of several critical elements. The extremely low chills inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present unique challenges. Material option is paramount; only materials with proven coherence and ductility at these temperatures, such as corrosion-resistant steel grades like 304L or 316L, or specialized bronze alloys, should be scrutinized. Furthermore, the apparatus's sealing capacity is vital to prevent spillages, requiring specialized stem sealing configurations and low-temperature oils. Finally, pressure scales and actuation techniques, taking into account potential pressure increases, must be thoroughly matched to the system's conditions. Neglecting these details can lead to disastrous failure and safety jeopardies.

Freezing Circular Valve Material Fitness Directory

Identifying the appropriate material for cryogenic orbital valves is paramount, given the rigorous temperatures involved. This catalog highlights common constituents and their performance when exposed to cryogenic fluids such as cryogen nitrogen, solution helium, and oxygen. Stainless steels, particularly classes 304 and 316, often demonstrate adequate toughness and degradation resistance, though martensitic compounds require careful consideration regarding susceptibility. Aluminum alloys can be suitable for certain applications, however, their flexibility and immunity to specific chemicals needs in-depth evaluation. Copper alloys, while offering some merits, may exhibit declined productivity at these low temperatures. Consultation with distributors and comprehensive examination is essential to assure lifespan and security in cryogenic tasks.

Elevating Dual Closure and Drain Framework Output

Realizing optimal efficiency in DBB installations hinges on a multifaceted strategy. Careful inspection of unit selection is paramount, with a focus on component agreement and force assessment. Regular assessment of vent corridors for interference is necessary, often entailing the use of exclusive monitoring instruments. Furthermore, procedure tuning—including analysis of transport rates and stress variation—can markedly augment overall arrangement soundness and defense. Finally, observance to manufacturer principles and the performance of a extensive servicing plan are unavoidable for long-term sustainability and stability.

best cryogenic ball valves

best cryogenic ball valves