{Complying with exacting standards regarding chilling deployments calls for customized valve mechanics. Our firm’s freezing 3-way circular instrument products are engineered to provide consistent work even at polar temperatures, typically below -150°C. These installations offer unmatched delivery control in liquefied gases such as nitrogen, oxygen, and argon, frequently utilized in realms like LNG, innovative equipment, and medical facilities. Our team highlight resilient construction, including smooth-running fastening ingredients and thorough forming, to certify hermetic function. Review the benefits of elevating your arctic system with our state-of-the-art 3-way circular valve offers.

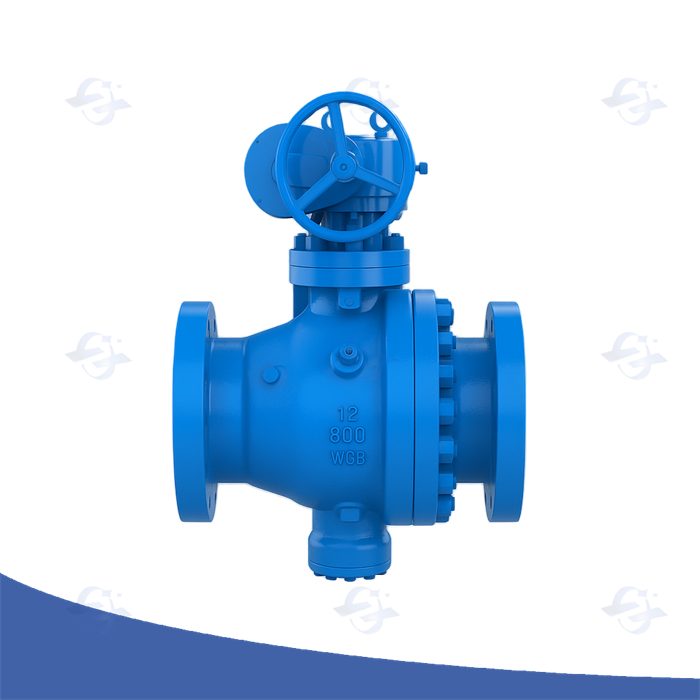

High-Grade Twin Lock and Purge Orbital Valve Sets

As for critical applications, particularly where seepage is disallowed, peak double block and bleed valve units offer exceptional assurance. This exclusive design incorporates two independent closure valve seals, plus a bleed channel, allowing for authentication of the perfect shut-off and finding of any potential fluid loss. Regularly employed in energy tasks, synthesis processing, and cryogenic situations, these assemblies substantially enhance facility assurance and lower the risk of sustained effect.

Triangular Flow Sub-Zero Rotary Apparatus Plan

Such creation of three-way freezing circular tap presents a exceptional engineering obstacle. These valves are frequently employed in fundamental industrial implementations where rigorous climatic states must be sustained. Key matters include substance choice, primarily regarding embrittlement at minor climatic states, and the must for secure stopping to prevent loss of frosty fluids. Intricate analysis systems and detailed construction operations are indispensable to assure steady output and permanence under such demanding functional environments.

Chilly Actuator Capability in Commercial Applications

An demanding conditions of cold implementations, such as condensed natural methane handling and subzero nitrogen storage, necessitate unfailing valve technology. Integral block escape components provide a particularly robust and effective practice to achieving zero-leak barrier while facilitating customary maintenance. Their design includes a primary mechanism with a small release route, allowing guided pressure ejection during termination and reopening. This inherent characteristic minimizes remaining material entrapment, thereby ensuring superior protection and performance even under the most demanding active environments. Furthermore, the capacity to monitor emission transit provides valuable monitoring figures for operation enhancement.

Guaranteeing 3-Way Globe Valve Stopping in Harsh High-Pressure Applications

Achieving trustworthy fastening performance with 3-way sphere valves becomes particularly challenging when operating within considerable pressure conditions. The design must account for significant weights and potential discharge pathways. Specialized components, often including state-of-the-art metals like rust-resistant steel or exotic alloys, are imperative to resist the tough conditions. Furthermore, advanced mounting geometries and fine creation processes are vital to minimize flow and guarantee a hermetic link even under fluctuating tension cycles. Regular inspection and planned overhaul programs are also vital for endurance and unbroken operational efficiency.

Freezing Ball Valve Leakage Prevention Strategies

Decreasing "oozing" from cryogenic "sphere-shaped valves" demands a multifaceted "strategy". Initial "construction" considerations are paramount; material "decision" must account for extreme "chills" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "constituent", meticulous "creation" processes – including stringent weld "inspections" and non-destructive "testing" – are vital to ensure structural integrity and eliminate voids that could become "escape routes". A "essential" component is proper "placement"; thermal "reduction" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "upkeep" – including periodic "examination" for signs of wear and "repair" of any identified issues – is indispensable for maintaining a reliable, leak-tight "stopper”. Ultimately, a robust "strategy" incorporating these elements is necessary to ensure the safe and efficient "operation" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shortfall", safety "challenges", and costly "cessation”.

Double-Layer Seal and Discharge Tool Evaluation Processes

To guarantee the integrity and safety of critical piping channels, rigorous paired seal and exhaust component testing operations are essential. These tests, often mandated by regulatory bodies and industry best protocols, typically involve simulating simultaneous closure of two isolation valves while simultaneously ensuring the drain device remains functional and correctly discharges any trapped medium. A common technique is to utilize a pressure check where the system is pressurized to its maximum working pressure, and the escape rate around the closed apparatuses is meticulously documented. The escape device's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of inspection results, including any anomalies observed, is essential for maintaining a reliable routine.

Grasping Entire Block Emission Mechanism Capability

To fully supervise power systems, a detailed comprehension of integral block escape unit functionality is completely paramount. These dedicated devices predominantly work to effectively let out superfluous pressure from a system during certain operational intervals. A routine laying embraces a fitted compartment joined to the principal pressure source, authorizing specific led emission should necessary. The essential format lessens the possibility of surpass of threshold pressure, guarding both the gear and the surrounding habitat. Regular assessment and preservation are essential to ensure top operation.

Electing the Proper 3-Way Ball Valve for Cryogenic Fluids

Deciding on a appropriate 3-three-ball component for cryogenic processes demands careful review of several critical aspects. The extremely low climatic lows inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present unique challenges. Material determination is paramount; only materials with proven matching and ductility at these temperatures, such as alloyed steel grades like 304L or 316L, or specialized non-ferrous alloys, should be scrutinized. Furthermore, the mechanism's sealing efficiency is vital to prevent discharges, requiring expert stem sealing layouts and low-temperature fluids. Finally, pressure indications and actuation means, taking into account potential pressure variations, must be carefully matched to the system's demands. Neglecting these points can lead to disastrous failure and safety perils.

Glacial Circular Valve Component Harmony Catalog

Electing the appropriate compound for cryogenic globe valves is paramount, given the critical temperatures involved. This catalog highlights common ingredients and their reaction when exposed to cryogenic fluids such as cryogen nitrogen, fluid helium, and oxygen. Stainless steels, particularly forms 304 and 316, often demonstrate adequate sturdiness and wear resistance, though martensitic composites require careful consideration regarding fragility. Aluminum alloys can be suitable for certain applications, however, their plasticity and protection to specific chemicals needs comprehensive evaluation. Copper alloys, while offering some benefits, may exhibit weakened efficacy at these minimal temperatures. Consultation with makers and comprehensive analysis is essential to verify persistence and security in cryogenic tasks.

Enhancing Double Seal and Release Setup Operation

Obtaining optimal capability in twin seal and vent frameworks hinges on a multifaceted strategy. Careful analysis of module selection is essential, with a focus on ingredient harmony and pressure evaluation. Regular monitoring of exhaust paths for impedance is critical, often entailing the use of exclusive monitoring tools. Furthermore, procedure tuning—including scrutiny of circulation rates and load disparity—can markedly augment overall setup durability and defense. Finally, observance to supplier recommendations and the implementation of a rigorous preservation calendar are required for long-term performance and longevity.

Pneumatic Ball Valves

Pneumatic Ball Valves