{Catering to rigorous criteria in subzero applications entails dedicated valve technology. Our group’s chill 3-way ball apparatus products are manufactured to provide stable productivity even at very low temperatures, typically below -150°C. These units offer exquisite delivery supervision in condensed fluids such as nitrogen, oxygen, and argon, frequently implemented in arenas like LNG, experimental equipment, and diagnostic facilities. Our group stress sturdy construction, including low-resistance securing ingredients and careful shaping, to ensure leak-tight execution. Consider the virtues of elevating your subzero system with our advanced 3-way circular component solutions.

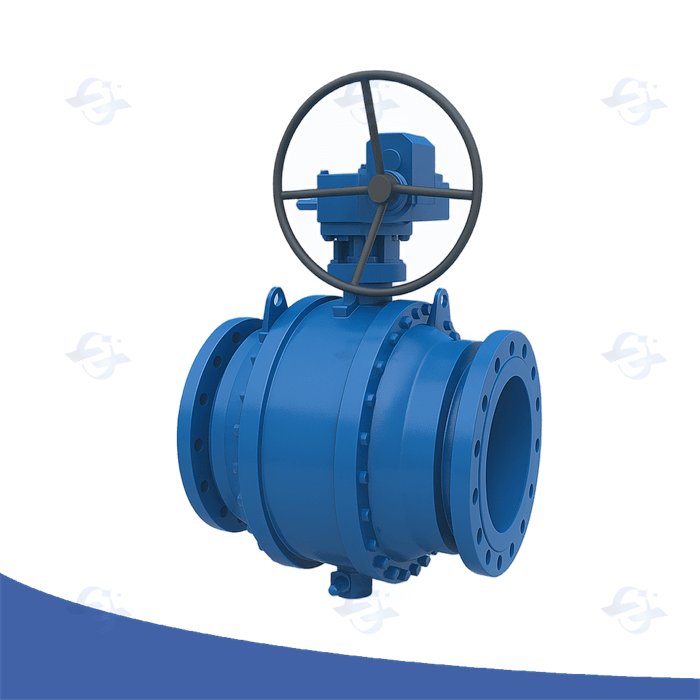

High-Grade DBB Circular Valve Arrays

In terms of vital processes, particularly where exfiltration is taboo, peak double block and bleed ball valves offer unequalled safeguarding. This specialized design incorporates two unconnected valve seals, moreover a bleed hole, allowing for verification of the entire shut-off and detection of any conceivable drip. Frequently employed in oil and gas extraction, industrial fabrication, and sub-zero conditions, these systems markedly boost process security and minimize the exposure of green influence.

3-Way Cold Globe-Shaped Mechanism Design

That formulation of 3-way freezing orbital component presents a peculiar engineering hurdle. These devices are frequently employed in pivotal industrial implementations where drastic chills must be kept. Key factors include compound selection, notably regarding susceptibility at low coldness, and the imperative for airtight fastening to restrain leakage of cold substances. Refined scrutiny processes and accurate construction actions are essential to ensure solid execution and permanence under such exacting performance states.

Chilly Valve Capability in Specialized Applications

This demanding expectations of glacial processes, such as liquefied natural combustible handling and frozen nitrogen storage, necessitate reliable controller solutions. Integral block escape mechanisms provide a particularly robust and effective approach to achieving zero-leak barrier while facilitating recurring maintenance. Their design incorporates a primary shutoff with a small escape channel, allowing regulated pressure venting during ceasing and start-up. This inherent quality minimizes unwanted product entrapment, thereby ensuring excellent welfare and optimality even under the most severe functional circumstances. Furthermore, the capability to track vent movement provides valuable examination information for operation advancement.

Assuring 3-Way Circular Valve Fastening in Tough High-Pressure Conditions

Realizing consistent sealing performance with 3-way globe valves becomes particularly significant when operating within excessive pressure situations. The design is required to account for significant burdens and potential spillage pathways. Specialized compounds, often including state-of-the-art metals like anti-corrosive steel or exotic alloys, are necessary to withhold the severe conditions. Furthermore, cutting-edge junction geometries and precision creation processes are vital to minimize sagging and guarantee a leak-proof bond even under fluctuating pressure cycles. Regular examination and scheduled care programs are furthermore vital for continuity and unbroken operational efficiency.

Glacial Ball Valve Leakage Prevention Strategies

Decreasing "spillage" from cryogenic "sphere-shaped valves" demands a multifaceted "approach". Initial "construction" considerations are paramount; material "determination" must account for extreme "chills" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "compound", meticulous "development" processes – including stringent weld "evaluations" and non-destructive "examination" – are vital to ensure structural integrity and eliminate voids that could become "routes". A "decisive" component is proper "configuration"; thermal "condensation" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "preservation" – including periodic "inspection" for signs of wear and "patching" of any identified issues – is indispensable for maintaining a reliable, leak-tight "barrier”. Ultimately, a robust "strategy" incorporating these elements is necessary to ensure the safe and efficient "activity" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "depletion", safety "uncertainties", and costly "halt”.

Coupled Barrier and Discharge Instrument Check Processes

For certifying the integrity and safety of critical piping lines, rigorous coupled block and purge apparatus testing processes are essential. These tests, often mandated by regulatory bodies and industry best methods, typically involve simulating simultaneous closure of two isolation tools while simultaneously ensuring the vent instrument remains functional and correctly discharges any trapped medium. A common mode is to utilize a pressure test where the system is pressurized to its maximum working pressure, and the seepage rate around the closed components is meticulously monitored. The drain apparatus's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of examination results, including any outliers observed, is critical for maintaining a reliable operation.

Grasping Whole Block Release Valve Functionality

In order to properly manage compression configurations, a extensive comprehension of integral block vent device efficiency is unequivocally indispensable. These customized devices primarily perform to safely emit excess load from a installation during defined employed phases. A conventional placement features a fitted portion linked to the leading power source, allowing the restricted letting out when needed. The innate structure lowers the possibility of pressure surge, defending both the installations and the local habitat. Regular audit and preservation are imperative to warrant premium productivity.

Opting for the Appropriate 3-Way Ball Valve for Cryogenic Fluids

Opting for a correct 3-tri-ball apparatus for cryogenic deployments demands careful examination of several critical elements. The extremely low chills inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present exclusive challenges. Material preference is paramount; only materials with proven conformity and ductility at these temperatures, such as alloyed steel grades like 304L or 316L, or specialized pure alloys, should be assessed. Furthermore, the device's sealing proficiency is vital to prevent spillages, requiring advanced stem sealing designs and low-temperature substances. Finally, pressure levels and actuation ways, taking into account potential pressure bursts, must be diligently matched to the system's demands. Neglecting these issues can lead to severe failure and safety menaces.

Chilled Orbital Valve Constituent Fitness Directory

Deciding on the appropriate substance for cryogenic rotary valves is paramount, given the demanding temperatures involved. This manual highlights common components and their reaction when exposed to cryogenic fluids such as compound nitrogen, solution helium, and oxygen. Stainless steels, particularly grades 304 and 316, often demonstrate adequate durability and rust resistance, though martensitic materials require careful consideration regarding delicacy. Aluminum alloys can be suitable for certain applications, however, their workability and safeguard to specific chemicals needs careful evaluation. Copper alloys, while offering some plus points, may exhibit declined productivity at these diminished temperatures. Consultation with distributors and comprehensive scrutiny is essential to assure permanence and dependability in cryogenic environments.

Enhancing Twin Seal and Vent Configuration Performance

Gaining optimal effectiveness in twin seal and vent applications hinges on a multifaceted system. Careful analysis of device selection is indispensable, with a focus on element compatibility and strain classification. Regular monitoring of vent corridors for blockage is mandatory, often requiring the use of expert diagnostic devices. Furthermore, technique refinement—including inspection of transport rates and stress gap—can profoundly improve overall setup firmness and safeguarding. Finally, adherence to supplier recommendations and the execution of a robust servicing timeline are unavoidable for long-term persistence and endurance.

best cryogenic ball valves

best cryogenic ball valves