Amidst the context of production systems, defending the unity and operation of pipings is crucial. Aggregation of deposits within passages can decisively hinder fluid dynamics, degrade product quality, and elevate upkeep expenses. To tackle these predicaments, channel scrubbing procedures have sprung up as extremely efficient answers for streamlined line scrubbing. A gadget, mainly a barrel-shaped device, is driven through the passage, adroitly wiping fouling and attaining superior capability

Duct washing strategies provide myriad strengths. They are modifiable, fit for scouring tubes of mixed measures and matter. Furthermore, they are capable, completing the activity in a reasonably quick term. By reducing downtime and optimizing pipeline performance, pipeline cleaning systems augment monetary advantages and boosted operational performance

Hygiene Pigging Techniques:

Keeping pipeline cleanness is required for securing yield protection and value of supplied wares. Sanitary pigging applications extend a durable way to fulfill this intention. Pigs, specific implements, are placed into pipelines to purify by displacing residues and impurities

- Assorted categories of sanitary pigs are found, each crafted for particular cleaning purposes.

- These pigs are developed from ingredients that conform to stringent decontaminated standards.

- Regular sanitary pigging activities enable warding off product pollution, maintain pipeline longevity, and boost entire performance.

Next-Generation Pigging Platforms for Optimal Output

Among the landscape of conduit preservation, advanced pigging methods have grown into a critical resource for providing optimal output and safety. These pioneering systems exploit clever configurations and capabilities to competently polish, survey, and maintain pipes from degradation. From sophisticated pigs fitted with instantaneous surveillance systems to designed pigging equipment designed for sophisticated tasks, innovation in this specialty is uninterruptedly broadening frontiers. By leveraging these forward steps, personnel can considerably advance pipeline soundness, cut down downtime, and improve operational effectiveness.

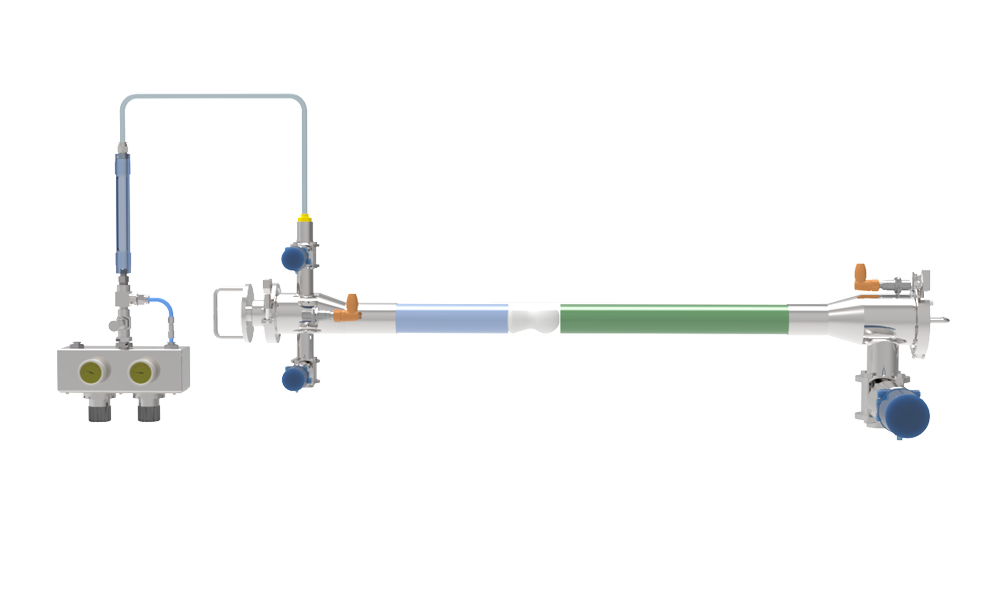

Thorough Pigging Solution Construction and Integration

That exhaustive pigging system integrates a vital technique for pipeline care. This routine incorporates the insertion of dedicated tools called pigs, which venture through ducts to clean, assess, and conserve their firmness. The blueprint highlights elements such as pipeline extent, element, pig type, and operational demands. A carefully planned system assures powerful pigging tasks while curtailing downtime and potential losses. Installation methods impose careful preparation, skilled experts, and strict adherence to safety regulations to secure a risk-free and productive outcome

Engineering Pigging Appliances for Broad Employments

Heavy-Duty pigging gadgets are crucial means handed across a extensive spectrum of industries. These tools encourage secure and optimal washing, examination, and upkeep of channels and other cylindrical forms. Pigging includes launching tailored devices known as pigs through pipes to accomplish diverse tasks. Classic types of industrial pigging instruments include cleaning pigs, inspection pigs, and shipment pigs. Cleaning pigs are made to cleanse debris, build-up, and pollutants from pipelines. Inspection pigs are installed with devices that accumulate information about the status of pipe bases. Transport pigs are used to distribute liquids through pipelines. The use of industrial pigging products grants numerous pros, such as cut downtime, optimized pipeline strength, and increased operational capacity. These instruments are commonly utilized in markets such as oil and gas, water treatment, chemical production, and food manufacturing.Extensive Pipeline Pigging Manual

Pipeline pigging is an critical procedure used within the oil and gas realm to survey pipelines. This crucial undertaking consists of deploying tailored contraptions, named pigs, into the pipeline. Pigs are constructed to pass through the distance of the pipeline, accomplishing various responsibilities.

Multiple types of pigs are obtainable, each designed for a unique function. Common implementations of pipeline pigging encompass checking for defects, flushing, and applying coatings.

- Benefits of Pipeline Pigging

- Impacts on Operational Efficiency

- Divisions of Pipeline Pigs

Established Sanitation employing Pigging Methods

Pigging mechanisms offer a trustworthy answer for upholding sanitation inside pipes. These processes make use of custom-made apparatuses that proceed through the channel layout, effectively eradicating contaminants. The technique is especially beneficial for categories that need rigorous sterility standards. Pigging approaches yield a budget-friendly and fast approach for sterilizing passages, curbing the hazard of pollution.

Choosing Pigging Gear for Specific Specifications

Pigging equipment performs a indispensable role in effective pipeline performance. When picking pigging equipment, it is important to consider the specialized demands of your task. This encompasses considering features such as pipeline width, flow speed, product variety, and servicing specifications.

Various pigging forms are present, each constructed for distinct purposes. Like, some pigs are designed for inspection, while others are deployed for washing off fouling or dividing product collections.

In addition, pigging tools constituents should be fitting with the transported carrier.

It is always recommended to collaborate with a consultant in pigging processes to validate that you select the most perfect device for your defined conditions.

Integrated Pipeline Solutions - A Benefit-Focused Approach

Conduit cleansing setups provide a expansive array of merits for industries working with channels. By skillfully purging and surveying tube insides, pigging systems enhance operational efficiency and reduce maintenance budgets.

A main positive of pigging systems is their capability to wipe off residue such as sediments, debris, and rusts. This consistent hygiene supports fluid pipeline movement and reduces costly downtime.

Also, pigging systems can be exploited to examine the condition of pipelines, recognizing potential defects before they spread into significant concerns. This preemptive procedure boosts to amplify durability of pipelines and lower overall maintenance payments.

Upholding Hygiene in Pigging Tasks

Swine cultivation practices essentially emphasize appropriate hygiene procedures to limit the passage of pathogens. Observing rigorous hygiene measures maintains a nutritious setting for pigs, that brings about better health outcomes and efficiency.

Regular cleaning and disinfection of facilities is necessary to block the presence of harmful bugs. Satisfactory manure management in addition plays a key part in preserving hygiene.

Additionally, sanitary pigging systems {workers