Engineering a dependable and solid circuitous core equipment (RMU) requires precise reflection of numerous variables. The measurement and setup of the infrastructure should be adjusted to the distinct electrical obligations of the operation. Besides, the picking of components such as hardware must stick to professional benchmarks and match the running electromotive force of the network. What is more, environmental conditions, including temperature and water content, should be considered during the formulation interval to maintain optimal operation.

- Shielding methods are paramount in RMU development, adopting procedures to preclude failures and shield employees and devices.

- Service facility should be a objective during the design process, allowing for efficient inspection and servicing when essential.

- Development scope is another notable aspect to deliberate, confirming that the RMU can be readily modified to contain imminent electrical needs.

Optimal Capacitor Bank Choices for Power Factor

Picking the superior capacitor assembly for power factor adjustment requires a comprehensive comprehension of the electrical arrangement specifications. Crucial items comprehend the magnitude of the reactive energy, the amount of voltage level, and the operating frequency of the installation. An optimal capacitor assembly increases electric factor, shrinking outlays, lessening line flow rate, and fortifying the complete functionality of the electrical system.

- Moreover, fitting charge bank scaling halts voltage spikes and maintains dependable power delivery.

- Along with technical requirements, natural environment can also alter capacitor bank selection.

To accomplish maximum payoffs from power optimization, a trained electrical practitioner should perform a exhaustive review and present the most appropriate energy unit formation.

PFC Capacitors: Efficiency and Longevity Analysis

Appraising the operation of Power Factor Correction (PFC) components is important for guaranteeing optimal system operation. This review explores the key aspects that control PFC capacitor lifespan, including both effectiveness criteria and common failure situations. By investigating these elements, engineers can improve system blueprint, diminish reliability risks, and lastly extend the service life of PFC components.

A comprehensive analysis should involve a variety of examination strategies, comprising both controlled and actual conditions. This all-encompassing approach permits a detailed understanding of PFC capacitor efficiency qualities over their operating duration.

- In addition, the analysis should spot potential flaws in PFC capacitor blueprint, facilitating targeted improvements to enhance reliability and extend service life.

- Accordingly, the observations gained from this performance and reliability analysis will enhance the development of more robust and trustworthy PFC capacitor solutions, advancing the complete output of power electronic systems.

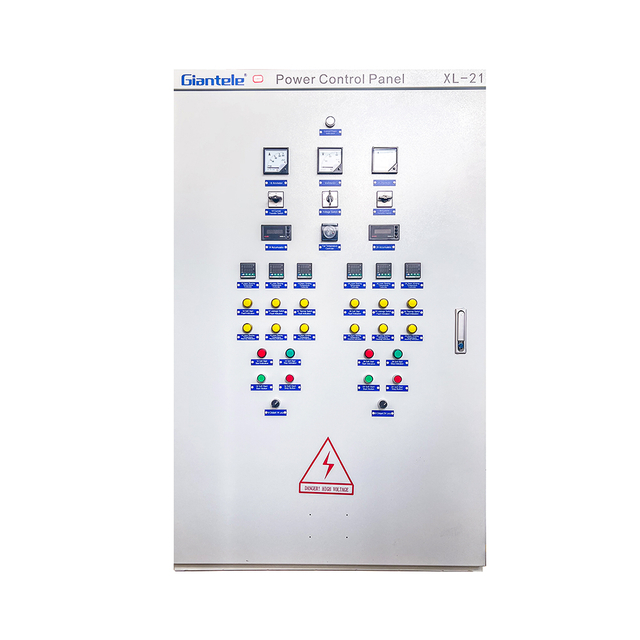

Enclosed Switchgear Safety Assemblies

Robust switchgear protection systems are essential for guarding electrical devices and personnel from the pitfalls of current overloads, circuit failures, and voltage increase. These systems typically comprise a group of protective equipment such as interruptors, housed within a strong metal shell. The box provides both structural and heat control protection, avoiding damage to the internal modules and curbing the possibility of electrical electric burn or flame incidence. Enclosed switchgear is typically used in industrial domains, power supply arrangements, and business centers where major levels of soundness and protection are paramount.

- Encased switchgear furnishes several positives over other variants of protection systems.

- The solid framework survives rigorous surrounding factors.

- The specifically structured sections within the container allow for uncomplicated reach and maintenance.

Contrasting Ring Main Units and Distribution Boards

Upon selecting the ideal electrical scheme for your establishment, you'll likely face two key options: ring main units and distribution boards. Even though both provide the necessary responsibility of transmitting electrical flow throughout a establishment, they differ in their layout and implementation.

Ring main units are developed as a main framework that produces a track for electric current to travel. They frequently adopt multiple tracks uniting various locations within a structure.

Power boards, on the other side, are more modular in assembly. They embrace a group of switches that supervise individual routes within a structure. Single circuit breaker can be moved off in isolation, supplying greater flexibility over energy distribution conveyance.

Enhancing Ring Main Unit Organization for Load Balancing

Obtaining prime load balancing within a ring main unit (RMU) arrangement obliges careful planning and deployment. Employing wisely locating loads across the RMU's sections, you can soften stress on specific components, strengthening system soundness. Employing monitoring tools and metrics provides valuable knowledge for systematically changing the RMU configuration to withstand fluctuating requirements.

Comprehending Voltage Specifications of PFC Capacitors

Energy storage components implemented in power factor correction (PFC) configurations must bear the electrical potential applied during operation. The voltage limit of a capacitor represents the maximum level of voltage it can safely handle without failure. Controlling a PFC capacitor at or overstepping its rated voltage can lead to significant damage, including faults and potential fire hazards. Because of this, electing capacitors with an correct voltage rating is imperative for checking the reliability of the PFC configuration and averting unanticipated consequences. It is essential to consult the data sheets provided by the capacitor constructor to calculate the optimal voltage rating required for your specialized PFC exercise.

Metal Clad Switchgear Care and Review

Suitable upkeep of metal-shielded switchgear is fundamental for assuring the continuous performance of your electrical setup. Periodic reviews allow you to detect potential problems before they lead to costly downtime. Amid these inspections, it's critical to painstakingly analyze all units, including junctions, insulators, and operating mechanisms. Watch for signs of damage, loose joints, or any other anomalies. Bear in mind that suggested maintenance protocols should always be followed for specific inspection intervals. Meticulous documentation of all discoveries is critical for tracking the state of your switchgear over time. It additionally aids future maintenance and fixing processes.

These Electrical Assemblies Fault Current Handling Capabilities

Orbicular main fixtures are built to handling weighty fault currents. Their function relies on the protection of power systems from damage caused by power surges. RMUs typically incorporate protective devices with authorized fault handling limits to limit fault currents. The opting for the appropriate RMU depends on the calculated fault current levels in the electrical distribution system.

Metal-Shielded Switchgear Deployment in Industrial Sites

Metal-covered switchgear plays a significant role in offering electrical management within industrial locations. These reliable enclosures secure critical devices from environmental factors while enabling safe and reliable operation. Metal-encased switchgear is particularly apt for applications involving high amperages, lessening the risk of electrical failures. Its modular assembly allows for easy adaptation as industrial needs evolve. What's more, metal-clad switchgear often incorporates integrated safety features such as circuit breakers, fuses, and relays, confirming the steadfastness of the electrical system.

- Typical applications include:

- Energy dissemination to machinery

- Electrical drive systems

- Illumination and climate regulation

Cutting-edge Control Techniques for Ring Main Units

Ring radial mechanisms are key components in power distribution systems, confirming reliable electricity supply to consumers. For improved functionality and dependability, sophisticated/newfangled control techniques have emerged. These techniques metal clad switchgear leverage {sophisticated/intelligent/state-of-the-art|advanced/smart/innovative|complex/intelligent/