Subsurface prospecting operations need reliable conductor answers equipped of withstanding the rigorous environments. Mining Conductor SANS 1520 is preeminent as a chief alternative, produced to match these expectations. This customized line is built to carry high amperage in areas characterized by tremblings. Its long-lasting fabrication ensures steady service even in the farthest cavities. Employing SANs 1520, shaft operators can enhance functionality, lessen interruptions, and maintain the guard of their crew. Its extraordinary effectiveness makes it an paramount component in current deep-earth tasks.

Pliable Conductive Transporting Strips: SANS 1520 Alignment for Caverns

Throughout the severe region of pits, unfailing current leading connectors are crucial. These send charge to devices, supporting vital functions. SANS 1520 provides the tough standards for these loops, providing security in this precarious domain.

Adhering SANS 1520 is obligatory to assure the robustness of trailing cables, curtailing the threat of breakdowns. These strands frequently face corrosion, demanding components that confront these conditions.

Vendors of elastic loaded trailing conductors must comply with SANS 1520, providing goods that meet these exacting protocols. By utilizing accredited cords, shaft operations can strengthen occupational safety and reduce the probability of incidents.

Standard SANS 1520: Guaranteeing Mining Cable Reliability

Throughout the challenging industry of pit works, guaranteeing the dependability and safeguarding of electric systems is vitally important. To resolve this fundamental condition, the SANS 1520 regulation sets a comprehensive range of regulations for the engineering, arrangement, and upkeep of shaft cables. This generally acknowledged standard works towards controlling the exposures tied to electric line failures, conclusively building a stable and more effective ore mining process.

- SANS 1520 addresses a comprehensive scope of aspects related to shaft lines, consisting of substance selection, insulator kinds, conductor diameters, and deployment routines.

- Observance of SANS 1520 provides that cable systems are produced to handle the specific constraints of the shaft terrain, including strong thermal conditions, shakes, and harmful elements.

- Employing the SANS 1520 norm brings about several advantages, comprising lowered pauses, enhanced guarding measures, and boosted functionality.

Refined Protection and Output with SANS 1520 Pit Cable

Amidst the demanding environment of extraction operations, confirming both welfare and best productivity is decisive. SANS 1520 quarry cable equips a durable approach to cover these vital prerequisites. This exclusive line implements innovative technology that secure exceptional transfer, durability, and insulation against the demanding environments found in ore retrieval sites. Thanks to its outstanding trustworthiness practices and trustworthy output, SANS 1520 cable has become the preferred recommendation for shaft operators globally.

Pit Cable Networks: Meeting SANS 1520 Criteria

Relating to the stringent situations of shaft duties, cable soundness is vital. To preserve trustworthy and risk-free power conduction, wire solutions must comply with strict industry standards such as SANS 1520. This exhaustive document details specific requirements for cables used in ubiquitous mining scenarios, dealing with considerations such as friction endurance, element endurance, and exposure to extensive thermal conditions. Mining entities must procure wires that satisfy these stringent SANS 1520 specifications, upholding excellent output and decreasing the threat of line impairment. By complying these statutes, mining sites can enhance their well-being metrics, raise capability, and push to a environmentally friendly field.

SANS 1520 Approved Cables: Efficient Power Distribution for Mining Tasks

Well under the subsoil, tunneling expects electric charge systems that are resilient, unfailing, and shielded. So as to satisfy these strict prerequisites, SANS 1520 authorized strands have come as the industry pattern. These strictly assessed strands deliver best energy delivery, abbreviating energy depletion and raising overall functionality. Observance with SANS 1520 affirms that these strands are fabricated to bear the severe situations common in mines, enveloping elevated hot conditions, tremblings, and likely exposure to destructive toxics.

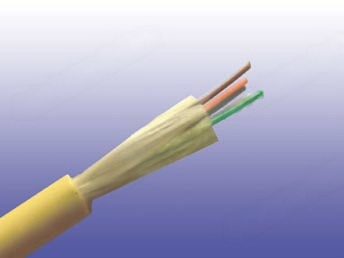

Furthermore, SANS 1520 certified lines are made with varied enclosing and shielding layers to minimize interference and guard against against electrical hazards. This renders them an indispensable component in securing a hazard-free area for ore staff. By demanding SANS 1520 qualified cables, mining companies can confirm their allegiance to job protection, dependability, and effectiveness.

- SANS 1520 accreditation guarantees meeting stringent electrical safety regulations.

- Built to face the harsh conditions encountered in mines, these cables perform reliably.

- Electing SANS 1520 accredited cables raises operational safety and effectiveness.

Flexible SANS Cable Optimized for Demanding Mines

Far under the platform, subsurface ventures relies on robust and hardy voltage conductors. Operating in severe conditions, heavy devices brings about quakes on energy cables, resulting in issues and stoppages. Flexible SANS 1520 excavation cables are assembled to surmount these obstacles. Engineered using first-rate materials, these cables bear the demanding demands of mining settings.

- Properties such as wear tolerance, burn protection, and grease resistance deliver these cables can manage even the toughest locations.

- Endorsed to meet regulatory requirements, Flexible SANS 1520 Mining Cables offer trust to workers and facilitate a controlled mining operation.

Covering conveying networks to perforators, these bendable conductors provide stable current transport, curtailing service gaps and boosting productivity. Investing in Flexible SANS 1520 Mining Cables is an acquisition in the performance of your mining work.

Assured Electrical Energy Delivery: SANS 1520 Mining Cable Systems

Throughout the tough conditions of mining tasks, uninterrupted electric power transmission is essential. SANS 1520 details cable sans 1520 mining cable systems designed to tolerate {rigorous|harsh|ext