Inside the exacting universe of erection, operation and delivery are crucial. To meet these needs, latest assembly apparatuses have developed to provide unsurpassed efficiency and dependability. Up-to-date leading fabrication equipment systems are equipped with modern solutions advancing capacity and decreasing natural impact. Extending over forceful diggers and conveyors to lithe jacks and petite instruments, these machines are designed to handle the most complex construction projects with ease.

- Sophisticated fluid systems allow for smooth and precise performance, resulting in increased accuracy and reduced downtime.

- Sturdy elements ensure that these machines can withstand the rigors of daily use in harsh environments.

- Green innovations minimize the environmental footprint of construction activities.

Concrete Production Units: Developed for Productivity

Batching plants serve as the crucial foundation of fabrication operations, validating concrete is formulated accurately and dependably. These sophisticated systems incorporate a range of cutting-edge technologies to maximize efficiency at every stage of the concrete production process. From the precise analysis of inputs to smooth integration and delivery functions, concrete production plants are developed to yield first-rate concrete matching tough criteria in modern assembly. By systematizing fundamental processes and lessening manual control, these setups assure constant production while raising overall efficacy.Stabilized Soil Plant Mixers Delivering Durable Foundations

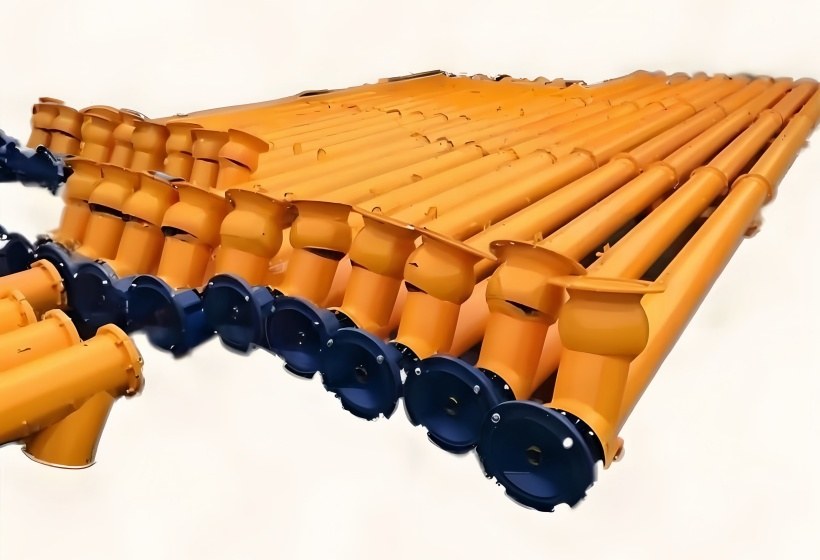

In the realm of construction, stability is paramount. When it comes to building durable foundations, stabilized soil mixing plants emerge as a top-tier resolution. These versatile machines competently integrate cementitious materials with original substrate, generating a fortified mass resistant to adverse conditions and longevity demands.

Supplying peerless strength and durability, stabilized soil equipment are indispensable for multiple projects, including roadways, spans, trails, and residential/commercial works. By harnessing the intrinsic capabilities of ground, these devices deliver an environmentally responsible technique for substructure fabrication.

Concrete Manufacturing Options for Different Endeavors

We recognize every building job is distinct and requires tailored cement approaches. For this reason, we extend multiple adjustable concrete manufacturing options suiting your distinct preferences. Be it a substantial commercial venture or a minor regional task, our proficiency and apparatus ensure premium concrete reliably. Our coalition of advisors works alongside clients to construct concrete manufacturing systems enhancing efficiency, reducing surplus, and delivering outstanding products. We offer a variety of components, including batching systems, mixing units, aggregate handling equipment, concrete pumps, control and monitoring systems. Our responsibility for client delight is determined. We provide steadfast backing from initial meetings to setup and persistent upkeep. Rely on us to enhance your progress, project after project.Mobile Batching Plants: Dynamic and Versatile

Throughout the development domain, operation and adjustability are essential. Mobile cement batching facilities supply a matchless response to these necessities, equipping developers with outstanding adaptability and movement on premises. Differing from immobile standard setups, these devices can be swiftly shifted to diverse areas, preventing costly and extended setup and breakdown operations. That fosters coordinated tasks, curtailed durations, and considerable fiscal advantages.

The transportability of movable concrete production systems unlocks various avenues for constructors. They can efficiently serve projects in remote locations, tight urban spaces, or anywhere where traditional plants are impractical. Also, the chance to fast relocate setups between jobs permits builders to optimize tools and reduce inactivity.

- Improved Yield: Minimize travel time and get projects moving faster with on-site mixing.

- Cutback in Charges: Eliminate the overhead of transporting large quantities of ready-mix concrete.

- Boosted Elasticity: Tackle a wider range of projects in diverse locations.

Boasting their condensed form and durable functionality, movable concrete production systems change the infrastructure field. They furnish engineers with apparatus essential to accomplish ventures proficiently, inexpensively, and with reliable correctness.

Exact Concrete Fabrication Using Modern Innovations

Current concrete fabrication faces a notable evolution as a result of implementing modern innovations. Computerized operations are introduced to guarantee exceptional correctness during every process segment, from raw batching to product output. Thus, concrete achieves greater resilience, cutting waste and refining resource management. Measurement instruments perform important duties in capturing current metrics on several variables during processing. Gathered input faces assessment to locate potentials for enhancement, enabling creators to steadily better operations and deliver persistently top-grade concrete. Gains from exact concrete assembly go beyond the creation procedure itself. Enhanced qualities of such innovative concrete result in more durable constructions, lowering upkeep expenses and prolonging building longevity.Establishing an Eco-Conscious Tomorrow through Innovative Development Machinery

The development domain witnesses a substantial shift, motivated by the imperative to lower its ecological damage. Innovative construction equipment are playing a crucial role in this shift towards a more sustainable future. Electrically driven apparatuses become widely adopted, cutting contaminants and sound disruption. In addition, developments in innovation create better equipment that handles materials efficiently. This evolution fosters ecological balance and raises productivity for erection companies.

The implementation of eco-friendly methods in the building industry is crucial for ensuring a habitable tomorrow. With the adoption of state-of-the-art devices and approaches, the industry assists in safeguarding nature for posterity.

Your Dependable Collaborator in Infrastructure Projects: Robust Machinery, Qualified Help

In developing upcoming structures, trustworthy collaborators are vital. That's where we come in. Our catalog contains rugged reliable instruments created to address hard projects. Our apparatuses incorporate modern technology securing highest efficiency and capability.

Yet, we act as more than simple tool vendors. Our team of experienced professionals provides unrivaled support every step of the way. From assessment to servicing, we facilitate you in upgrading your assembly operations.

- Our support involves elaborate learning initiatives to make your team competent in secure and efficient tool use

- Furthermore, we have round-the-clock professional help to answer questions and manage problems swiftly

- Our promise highlights delivering equipment and mastery critical to satisfy your creation goals

Robust Concrete Mixing

Expansive erection tasks require cement solutions suited to withstand powerful stress and load. Powerful concrete assembly methods respond to this requirement by supplying resilient mixes created for flyovers, towers, and underground routes. Such dedicated systems employ resilient tools designed to process ample volumes of elements, binders, and additives. Accurate calculations guarantee uniform standards and adherence to rigorous construction regulations

- Sophisticated management platforms enhance mixing precision and productivity

- Applying quality materials boosts the resilience of the blend

- Resilient batching systems provide critical support for erection advancement impacting habitual activities

Refining Building Practices: Improved Concrete Handling and Distribution

Within the rapid environment of building, productivity is critical. A key aspect of achieving this lies in optimizing your mixing and delivery processes. By following established protocols, you should appreciably reduce refuse, lower charges, and upgrade comprehensive productivity. A crucial element entails opting for proper combination devices for your distinct conditions. Be it a transportable mixer for small undertakings or a sturdy unit for major projects, ensure it accommodates the amount of materials necessary. Likewise, upgrade your distribution channels to lessen transit durations and gasoline costs.

- Using an approach to monitor resource deployment helps uncover places for refinements

- Scheduled upkeep of your blending and distribution tools is vital to preserve best functionality and lifespan

Complete Concrete Construction Process

Within the field of building, cement serves as a cornerstone of robustness and longevity. Furnishing full-range solutions across your concrete project is our enthusiasm. {From the initial design to the final finish, we offer a wide range of services tailored to meet your specific needs|Starting with early planning and ending with ultimate completion, we provide a broad array of solutions customized for your unique requirements|Beginning with conceptualization and concluding with final polish, we deliver extensive services adapted to your particular demands|From preliminary drafting to ultimate execution,

Within the challenging realm of building, performance and yield are vital. To address these necessities, current fabrication devices have improved to provide unequaled operation and consistency. Current top-tier erection machinery alternatives are equipped with modern solutions advancing capacity and decreasing natural impact. Encompassing durable scoopers and lifters to agile winches and compact contraptions, these equipment are created to master the most challenging assembly jobs comfortably.

- Enhanced mechanical drives allow for smooth and precise movement, resulting in increased accuracy and reduced downtime.

- Durable components ensure that these machines can withstand the rigors of daily use in harsh environments.

- Environmentally conscious mechanisms minimize the environmental footprint of construction activities.

Concrete Production Units: Developed for Productivity

Concrete mixing installations represent the fundamental base of construction tasks, ensuring concrete is manufactured with exactness and regularity. These advanced platforms incorporate various innovative devices to amplify capacity throughout the concrete formulation steps. From the precise assessment of constituents to optimized fusion and emission activities, concrete manufacturing units are constructed to offer excellent concrete complying with exacting standards in present-day erection. By facilitating important activities and curbing hands-on participation, these frameworks secure dependable yield while advancing broad productivity.Stabilized Soil Plant Mixers Delivering Durable Foundations

Throughout the environment of erection, durability is indispensable. When it comes to building durable foundations, stabilized soil mixing plants emerge as a leading solution. These versatile machines capably fuse solidifying additives with local ground, forming a durable structure designed to survive harsh elements and time.

Affording extraordinary robustness and longevity, soil stabilizing machines hold key positions in assorted enterprises, embracing parkways, bridges, lanes, and urban/rural establishments. By leveraging the natural strength of earth, these machines provide a sustainable method for base building.

Cement Facility Options for Each Venture

We appreciate every erection venture is particular and necessitates personalized concrete methods. Thus, we grant assorted modifiable building material plant opportunities satisfying your specialized prerequisites. Whether overseeing a broad municipal initiative or a small district-focused effort, our experience and equipment deliver first-class concrete unfailingly. Our staff of specialists cooperates with stakeholders to create concrete production systems boosting performance, decreasing discard, and attaining superior achievements. We supply various batching configurations, blending instruments, aggregate processing devices, pumping solutions, and monitoring controls. Our commitment to customer satisfaction is unwavering. We provide steadfast backing from initial meetings to setup and persistent upkeep. Enable us to aid your advancement, piece by piece.Mobile Concrete Mixing Plants: Unmatched Flexibility and Mobility

Inside the fabrication environment, performance and resilience are significant. Movable concrete production plants present an unrivaled fix for these challenges, furnishing engineers extraordinary flexibility and portability at work zones. Contrary to fixed conventional facilities, these modules are readily moved across sites, avoiding expensive and protracted assembly and dismantling activities. That encourages organized workflows, shortened project lengths, and remarkable monetary savings.

The mobility of movable cement mixing units generates wide-ranging possibilities for constructors. They facilitate productive backing for assignments in secluded spots, cramped urban environments, or wherever conventional plants cannot operate. What's more, the ability to rapidly transport plants among tasks allows contractors to boost resource use and curtail idle times.

- Amplified Effectiveness: Minimize travel time and get projects moving faster with on-site mixing.

- Decreased Outlays: Eliminate the overhead of transporting large quantities of ready-mix concrete.

- Greater Adaptability: Tackle a wider range of projects in diverse locations.

Boasting their condensed form and durable functionality, movable concrete production systems change the infrastructure field. They furnish engineers with apparatus essential to accomplish ventures proficiently, inexpensively, and with reliable correctness.

Accurate Concrete Manufacturing via Cutting-Edge Systems

Contemporary concrete manufacturing experiences a significant transformation due to adoption of cutting-edge systems. Robotic technologies get utilized to reach unmatched accuracy throughout each phase, spanning from ingredient batching to ultimate delivery. Subsequently, concrete presents enhanced solidity, curtailing refuse and maximizing material deployment. Detection tools fulfill key responsibilities in recording immediate insights about different criteria during assembly. Gathered input faces assessment to locate potentials for enhancement, enabling creators to steadily better operations and deliver persistently top-grade concrete. Values of pinpoint concrete production reach beyond the construction phase itself. Augmented features of state-of-the-art concrete yield robust frameworks, cutting maintenance outlays and increasing building endurance.Promoting a Green Era with Sophisticated Fabrication Equipment

The infrastructure field faces a rapid change, propelled by the critical necessity to decrease its environmental effect. Progressive fabrication apparatuses have essential roles in this evolution towards green practices. Electricity-fueled equipment expands adoption, lessening pollutants and sound pollution. What's more, evolution in machinery leads to improved devices that consume supplies thoughtfully. This evolution fosters ecological balance and raises productivity for erection companies.

The utilization of sustainable techniques in the erection space is indispensable for maintaining a livable planet. With the use of leading-edge tools and solutions, the industry participates in protecting the earth for upcoming generations.

A Trusted Supporter in Infrastructure Expansion: Sturdy Machinery, Skilled Services

When making modern building projects, dependable connections are fundamental. We provide that support. We furnish robust heavy-duty machines tailored to handle tough activities. Our devices include state-of-the-art systems ensuring superior operation and results.

But we're more than just equipment suppliers. Our squad of proficient advisors furnishes unmatched help across each step. From study to maintenance, we assist you in advancing your creation projects.

- We provide thorough coaching workshops to enable your workforce for safe and optimal apparatus operation

- Also, we grant immediate professional service to respond to your problems and questions competently

- Our dedication focuses on delivering resources and knowledge necessary to realize your building objectives

Large-Scale Concrete Production

Broad assembly operations demand concrete techniques prepared to handle intense strain and force. Resilient cement batching technologies tackle this issue by producing strong blends intended for overpasses, high-rises, and underground passages. Such dedicated facilities employ sturdy machinery able to process massive quantities of materials, binders, and additives. Accurate calculations guarantee uniform standards and adherence to rigorous construction regulations

- Advanced control systems optimize batching accuracy and efficiency

- Implementing refined materials strengthens the robustness of the batch

- Reliable cement batching facilities are indispensable for construction improvement shaping everyday conditions

Refining Building Practices: Improved Concrete Handling and Distribution

In the fast-paced world of construction, efficiency is paramount. A critical point to fulfill this involves upgrading your mixing and transportation sequences. By embracing recommended approaches, you might substantially diminish residue, shrink expenditures, and augment overall output. A key point is selecting appropriate batching machinery for your particular requirements. Be it a compact blender for small projects or a powerful unit for wide operations, confirm it accommodates the volume of materials demanded. Moreover, streamline your shipment courses to cut down travel intervals and fuel costs.

- Using an approach to monitor resource deployment helps uncover places for refinements

- Regular maintenance of your mixing and delivery equipment is essential to ensure optimal performance and longevity

Concrete Solutions from Start to End

Inside the domain of infrastructure, concrete acts concrete batching plant and stabilized soil mixing plant as a foundation of solidity and endurance. Supplying thorough assistance during every step of your cement operation is our dedication. {From the initial design to the final finish, we offer a wide range of services tailored to meet your specific needs|Starting with early planning and ending with ultimate completion, we provide a broad array of solutions customized for your unique requirements|Beginning with conceptualization and concluding with final polish, we deliver extensive services adapted to your particular demands|From preliminary drafting to ultimate execution,